Revised high angle rescue procedures and training have improved the performance of the Flynn Rescue Teams’ timing, ease of operation and efficiency. This success was prompted by the dedicated collective efforts of the entire Flynn team at 120-130 Adelaide, comprised of: glaziers, ironworkers, project management and the site safety specialists working together to improve the Flynn safety culture.

High angle rescue drills were completed on site by all shifts between Sept 26 to 28, 2018. Although the initial drill results were satisfactory, numerous questions and issues arose in-an-effort to improve the efficiency and organization of the rescue drills.

The Flynn health and safety management team began to improve the process with an initial meeting of site safety management specialists, team commanders and lead-hands, to communicate suggestions, concerns and critiques, in order to improve the procedures. These observations and suggestions were invaluable and resulted in positive gains in improving the preparation of equipment and storage and security of the rescue system.

Due to the size, scale and variable site-specific aspects of the project, additional professional and on-site consultation was utilized from Flynn safety equipment providers and the input the world class high angle rescue consultants. As a result, improvements were applied to modify the existing rescue system procedure and adding a simplified approved back-up system.

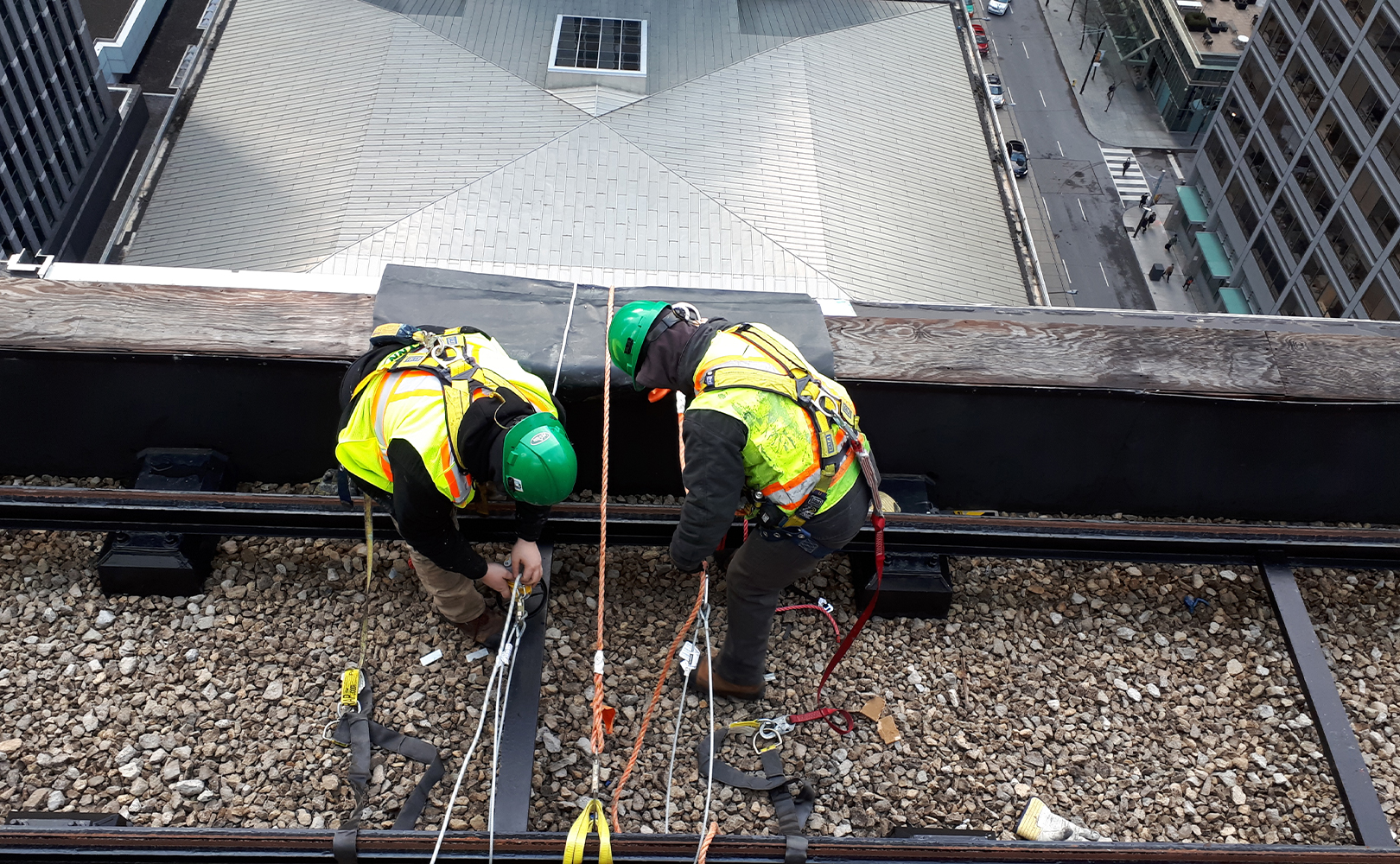

With instruction from Flynn rescue specialist Avi Raveh, two additional training sessions were completed for each shift, between November 3 to December 5, 2018. The first drill familiarized the rescue teams with the modified equipment and the second drill provided a hands-on high angle rooftop rescue simulation.

Team confidence was clearly-evident with improved trial set-up times of approximately 60-70%. Shout out to Flynn safety, project management and rescue teams for a fantastic effort!

Thank-you Flynn team!